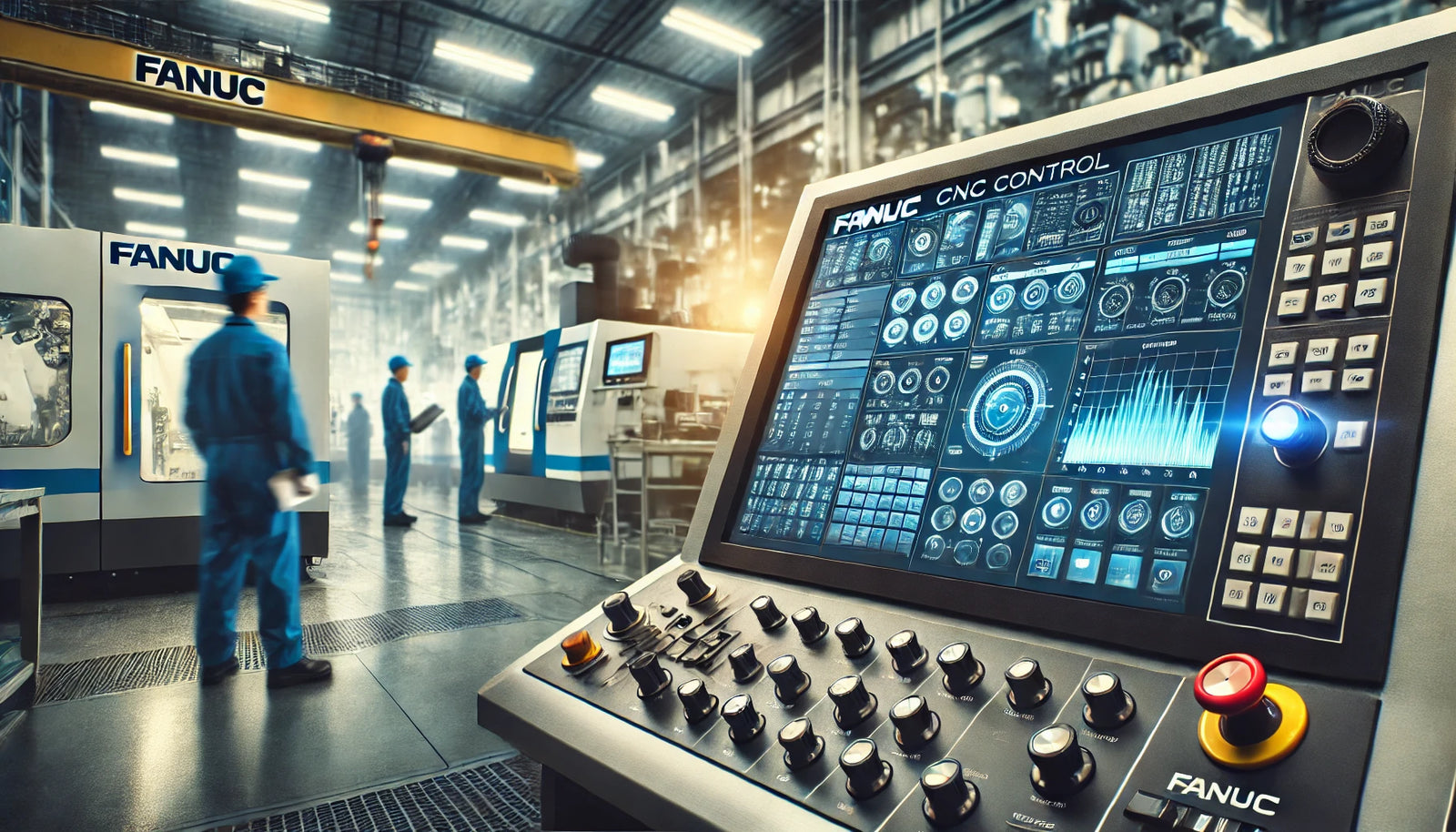

In the world of Computer Numerical Control (CNC) systems, FANUC has long been a dominant force, setting industry standards for precision, reliability, and innovation. Despite the emergence of numerous competitors, FANUC CNC controls continue to be regarded as the best choice for manufacturers worldwide. Here’s why FANUC CNC controls remain the gold standard in the industry:

1. Unmatched Reliability

FANUC is synonymous with reliability. Their CNC controls are known for their robust construction and dependability, ensuring that production lines keep running with minimal downtime. The high-quality components and rigorous testing processes FANUC employs mean that their systems can withstand the demands of even the most challenging manufacturing environments. This reliability translates to consistent, high-quality output and lower maintenance costs.

2. Advanced Technology and Innovation

FANUC has a long history of technological innovation. They continuously invest in research and development to stay ahead of the curve. The company’s CNC controls feature cutting-edge technology, including advanced motion control, high-speed processing, and superior precision capabilities. These innovations allow manufacturers to achieve greater accuracy and efficiency, pushing the boundaries of what’s possible in modern machining.

3. Comprehensive Support and Training

One of the standout features of FANUC is their extensive support network. They offer comprehensive training programs, technical support, and resources to ensure that users can fully leverage their CNC systems. FANUC’s global presence means that support is available virtually anywhere in the world, providing peace of mind and ensuring that help is always at hand when needed.

4. Scalability and Flexibility

FANUC CNC controls are highly scalable and adaptable to a wide range of applications. Whether you’re running a small workshop or a large-scale manufacturing operation, FANUC systems can be tailored to meet your specific needs. Their controls support a variety of machine types, from lathes and mills to complex multi-axis machines, making them suitable for diverse industries and applications.

5. Integration with Industry 4.0

As manufacturing moves towards Industry 4.0, the integration of smart technologies and data analytics becomes increasingly important. FANUC CNC controls are designed to seamlessly integrate with IoT (Internet of Things) platforms, enabling real-time data collection and analysis. This connectivity allows for predictive maintenance, remote monitoring, and optimization of production processes, driving efficiency and innovation.

6. User-Friendly Interface

Despite their advanced capabilities, FANUC CNC controls are known for their user-friendly interfaces. The intuitive design makes it easier for operators to program and control machines, reducing the learning curve and increasing productivity. FANUC’s focus on usability ensures that even complex machining tasks can be handled with ease, enhancing overall operational efficiency.

7. Energy Efficiency

In today’s environmentally conscious world, energy efficiency is a key consideration. FANUC CNC controls are designed to optimize energy use, reducing power consumption without compromising performance. This not only lowers operational costs but also supports sustainable manufacturing practices, making FANUC a responsible choice for eco-conscious businesses.

8. Long-Term Value

Investing in FANUC CNC controls offers long-term value. Their durability, combined with the continuous updates and improvements provided by FANUC, ensures that these systems remain relevant and effective for many years. The lower maintenance and operational costs, coupled with the high resale value of FANUC equipment, make them a wise investment for any manufacturing business.

Conclusion

FANUC CNC controls have earned their reputation as the best in the industry through a steadfast commitment to quality, innovation, and customer satisfaction. Their reliability, advanced technology, comprehensive support, and integration with modern manufacturing practices make them an unparalleled choice for manufacturers seeking to optimize their operations. As the industry continues to evolve, FANUC remains at the forefront, setting the standard for excellence in CNC controls. Investing in FANUC means investing in a future of precision, efficiency, and sustained success.