Key Features to Look For

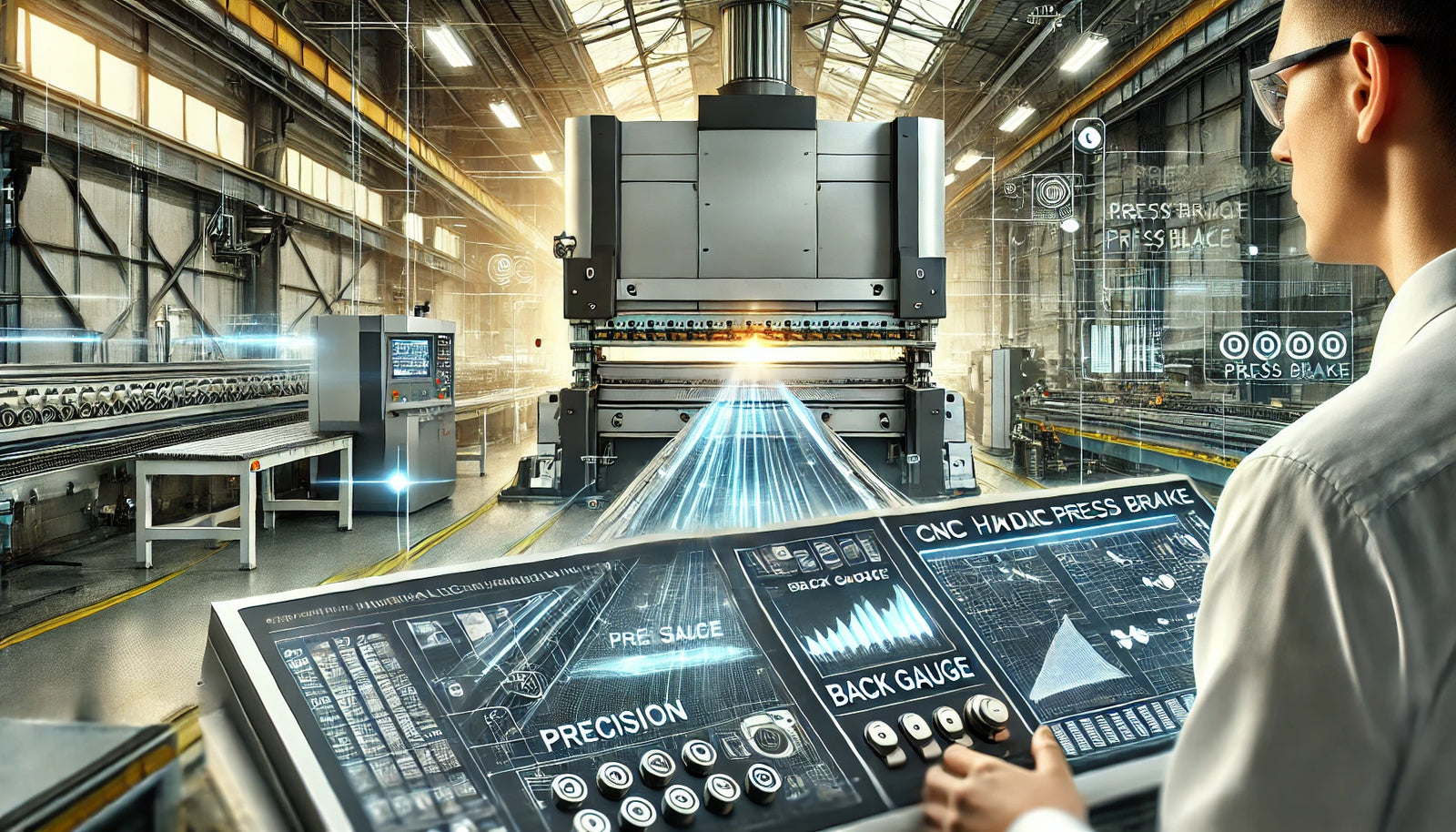

When it comes to precision metalworking, investing in the right equipment is crucial. CNC hydraulic press brakes are essential for bending and shaping metal sheets with high accuracy and efficiency. Whether you're upgrading your existing machinery or expanding your operations, selecting the right CNC hydraulic press brake can make a significant difference in your productivity and product quality. Here are the key features to look for when investing in a CNC hydraulic press brake:

1. Bending Capacity and Size

The first factor to consider is the bending capacity of the press brake. This includes both the maximum bending length and the maximum tonnage. Ensure that the press brake you choose can handle the thickness and width of the materials you typically work with. A press brake with a higher tonnage rating can accommodate thicker materials and more complex bends.

2. Control System

The control system is the brain of your CNC hydraulic press brake. Look for a press brake with a user-friendly, intuitive control interface. Modern CNC controls offer advanced features such as touchscreens, programmable bending sequences, and real-time feedback. These features can significantly enhance the precision and efficiency of your operations.

3. Backgauge System

The backgauge system is crucial for accurate positioning of the material before bending. An advanced backgauge system should offer high precision, repeatability, and flexibility. Consider models with programmable backgauges that allow for quick adjustments and automation for complex bending tasks.

4. Tooling and Dies

The tooling and dies you use with your press brake will affect the quality and versatility of your bends. Look for a press brake that supports a wide range of tooling options and offers easy tool changes. Quick-change tooling systems can save time and reduce downtime, increasing your overall productivity.

5. Hydraulic System

The hydraulic system is responsible for providing the force needed to bend the material. A high-quality hydraulic system should offer consistent and reliable performance. Look for features such as adjustable pressure settings and efficient hydraulic circuits to ensure precise and smooth operation.

6. Safety Features

Safety is paramount in any industrial setting. Ensure that the press brake you invest in comes with comprehensive safety features. Look for models with automatic safety systems, such as light curtains, safety mats, and emergency stop functions. Proper safety features help protect operators and reduce the risk of accidents.

7. Build Quality and Durability

The build quality of the press brake affects its longevity and performance. Invest in a press brake constructed from high-quality materials and designed for durability. A robust machine with a solid frame and high-quality components will provide reliable performance and a longer service life.

8. Ease of Maintenance

Routine maintenance is essential for keeping your press brake in optimal condition. Choose a model that offers easy access to critical components for routine maintenance and repairs. Manufacturers that provide detailed maintenance guides and support services can also be beneficial.

9. Energy Efficiency

In today’s eco-conscious environment, energy efficiency is an important consideration. Look for press brakes that offer energy-saving features, such as variable displacement pumps and efficient hydraulic systems. Energy-efficient models not only reduce operational costs but also contribute to a more sustainable operation.

10. Manufacturer Support and Warranty

Finally, consider the manufacturer’s support and warranty offerings. A strong warranty and responsive customer support can provide peace of mind and protect your investment. Ensure that the manufacturer offers comprehensive training, technical support, and readily available spare parts.

Conclusion

Investing in a CNC hydraulic press brake is a significant decision that can impact the efficiency and quality of your metalworking operations. By carefully evaluating these key features, you can select a press brake that meets your specific needs and helps you achieve your production goals. Take the time to research and consult with experts to make an informed decision, and you’ll be well on your way to enhancing your metalworking capabilities.

Feel free to reach out if you have any questions or need further guidance on choosing the right CNC hydraulic press brake for your needs!