Essential Safety Practices for Operating Industrial Hydraulic Presses

Introduction

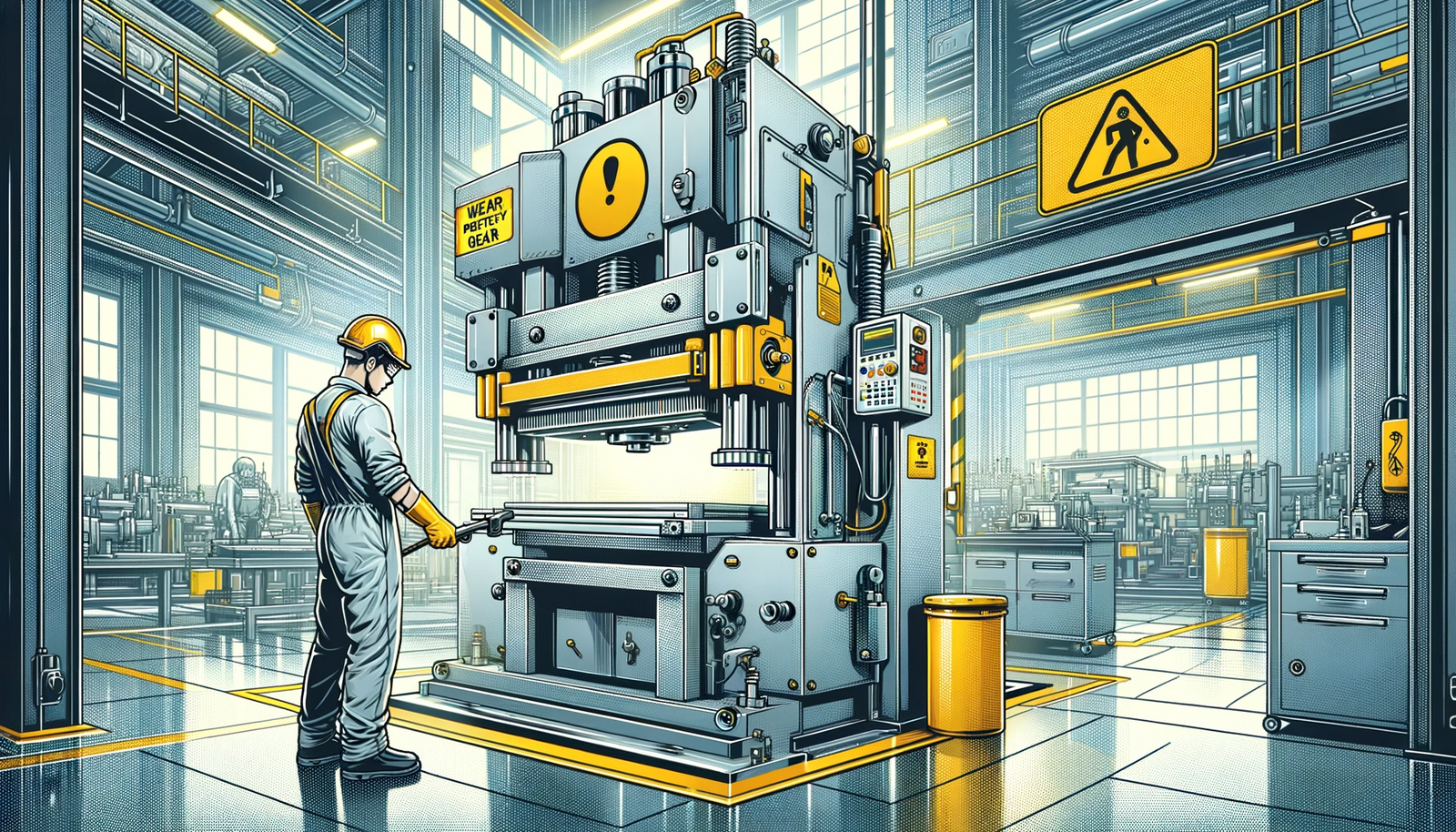

Industrial hydraulic presses are powerful tools that play a critical role in manufacturing and fabrication processes. However, their power and complexity demand respect and adherence to safety protocols. This blog post aims to outline essential safety practices to ensure a safe working environment while operating hydraulic presses.

Understanding the Risks

Before diving into safety practices, it's crucial to understand the risks involved in operating hydraulic presses. These risks include the potential for crush injuries, entanglement in moving parts, and hazards from flying debris or broken components.

Essential Safety Practices

Regular Maintenance and Inspection

- Routine Checks: Conduct regular inspections to ensure all parts of the hydraulic press are in good working condition.

- Professional Maintenance: Schedule regular maintenance by qualified technicians to identify and fix potential hazards.

Proper Training and Operation

- Comprehensive Training: Ensure that all operators are thoroughly trained in using the hydraulic press, including emergency procedures.

- Clear Operating Procedures: Establish and enforce clear operating procedures, including the use of control systems and emergency stops.

Personal Protective Equipment (PPE)

- Essential Gear: Operators should always wear appropriate PPE, including safety glasses, gloves, and ear protection.

- Safety Guards: Use safety guards and barriers to protect against flying debris and accidental contact with moving parts.

Safe Work Environment

- Organized Workspace: Keep the area around the hydraulic press clear and free of clutter to avoid tripping or falling hazards.

- Adequate Lighting: Ensure the work area is well-lit to improve visibility and reduce the risk of accidents.

Emergency Preparedness

- Emergency Stops: Familiarize all operators with the location and use of emergency stops.

- First Aid and Reporting: Have a first aid kit readily available and ensure incidents are promptly reported and investigated.

Conclusion: Safety as a Priority

The power of hydraulic presses makes them invaluable in industrial settings, but this power comes with significant responsibilities. Prioritizing safety through regular maintenance, proper training, use of PPE, maintaining a safe work environment, and being prepared for emergencies is crucial. By adhering to these essential safety practices, businesses can ensure the well-being of their employees and the efficient operation of their hydraulic presses.

---

Remember, safety in the workplace, especially when dealing with powerful machinery like hydraulic presses, is paramount. This blog post aims to raise awareness and encourage best practices for a safer working environment.