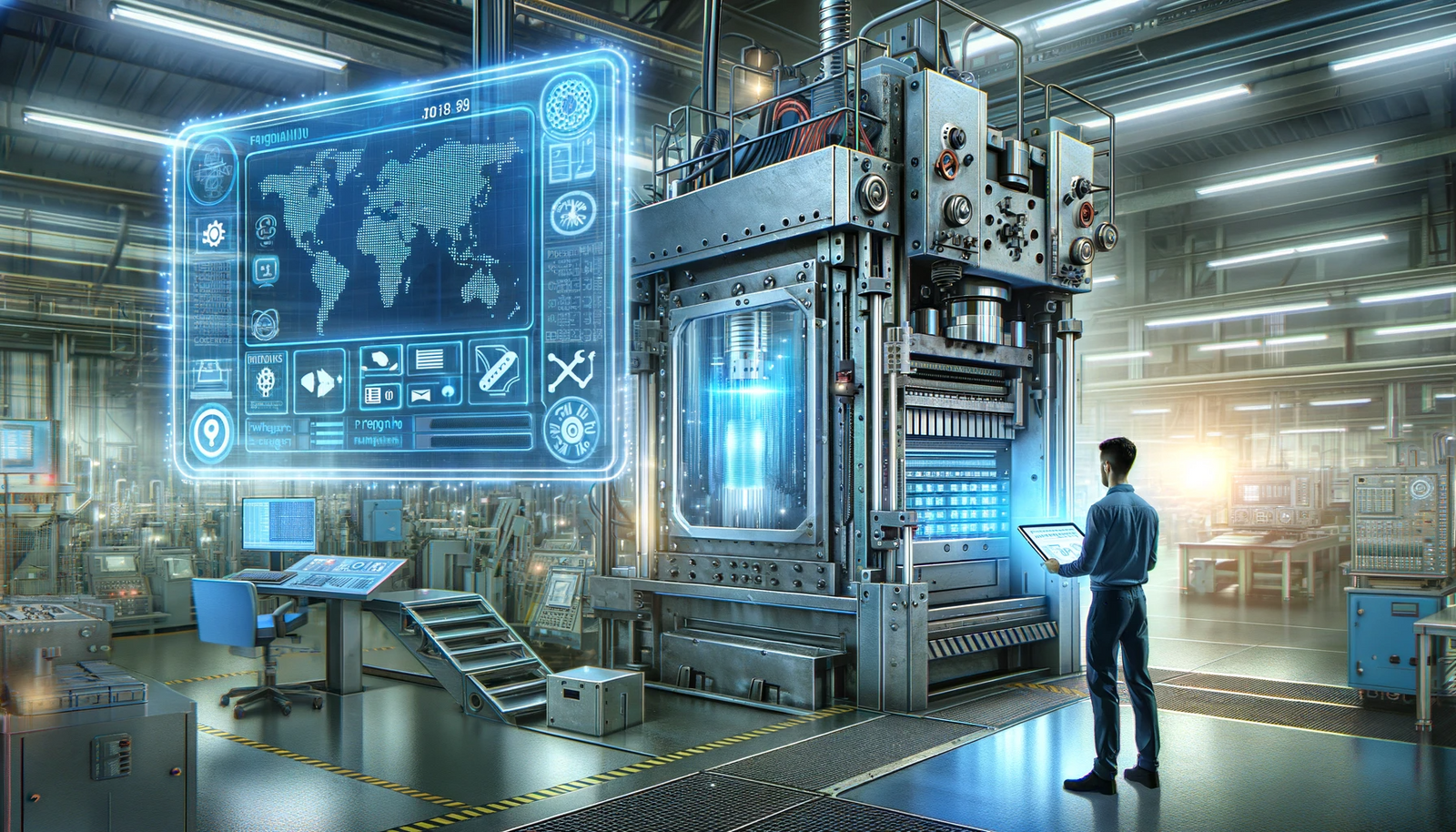

Navigating the Future of Manufacturing with Technology Integration

Introduction

In the era of Industry 4.0, the integration of programming and automation into hydraulic presses signifies a major leap in manufacturing efficiency and precision. This blog post explores how the infusion of advanced technology into these powerful machines is reshaping the industrial landscape.

The Evolution of Hydraulic Presses: From Manual to Automated

The journey of hydraulic presses from manual operation to sophisticated automated systems reflects the broader trajectory of industrial innovation. Early hydraulic presses required manual control for every cycle, limiting their speed and consistency. Today, programmable logic controllers (PLC) and computer numerical control (CNC) systems have transformed these machines into highly efficient, precise, and reliable tools.

Case Study: Automotive Industry's Leap in Efficiency

Example: Tesla's Manufacturing Line: In the automotive industry, the integration of automation in hydraulic presses has been a game-changer. Tesla, known for its innovation, employs automated hydraulic presses to fabricate parts for its electric vehicles. This automation allows for rapid, consistent production of high-quality components, essential in meeting the growing demand for electric vehicles.

Aerospace: Achieving Precision at Scale

Example: Airbus' Production Facilities: In aerospace, where precision is non-negotiable, automated hydraulic presses are instrumental. Airbus, for instance, uses highly programmed presses for forming aircraft components. These presses ensure that parts meet exact specifications, a critical factor in the safety and performance of aircraft.

The Role of Software in Hydraulic Press Automation

Advancements in software have been pivotal in the automation of hydraulic presses. Modern programming allows for intricate control over press operation, including pressure, speed, and duration of press cycles. This precision is vital in industries requiring high levels of customization and quality control.

The Impact on Labor and Skill Requirements

As hydraulic presses become more automated, the skill set required to operate them evolves. Operators now need a blend of mechanical understanding and programming skills. This shift emphasizes the importance of continual learning and adaptation in the workforce, aligning with the changing technological landscape.

Safety and Efficiency: A Dual Benefit

Automated hydraulic presses offer enhanced safety features, reducing the risk of operator injury. Sensors and safety guards, integrated through programming, can halt operation if a potential hazard is detected. Additionally, automation leads to improved efficiency, with machines capable of running longer hours with minimal human intervention.

Conclusion: Embracing the Future of Manufacturing

The programming and automation of hydraulic presses symbolize the broader trend of digital transformation in manufacturing. These technological advancements not only boost efficiency and precision but also open new possibilities for innovation in product design and production. As we look to the future, the continued evolution of hydraulic press technology will undoubtedly play a key role in driving industrial progress.

---

This blog post highlights the transformative impact of integrating programming and automation into hydraulic presses, underscoring the advancements and benefits brought to various industries.