Tracing the Development of a Revolutionary Machine

Introduction

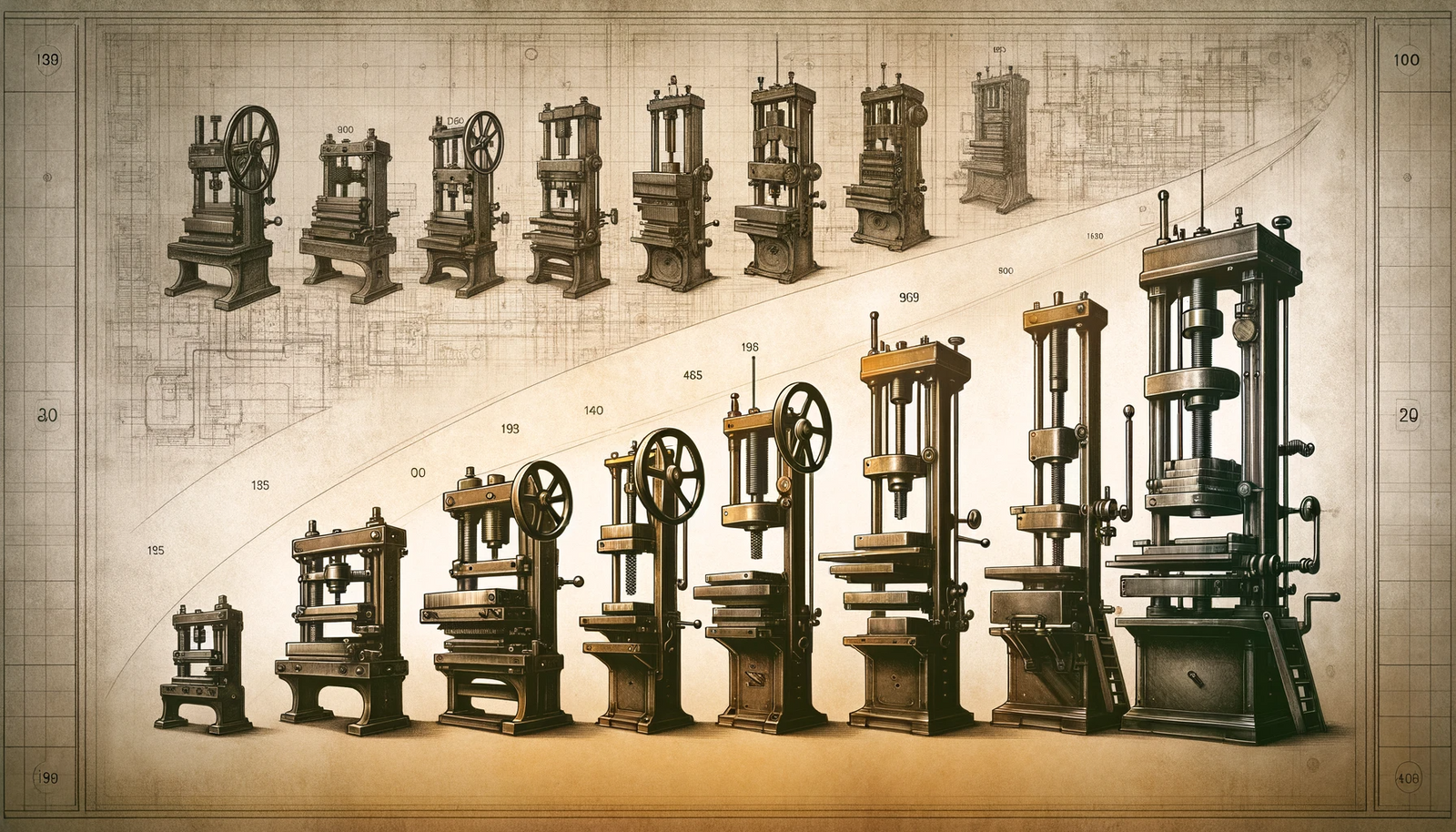

The hydraulic press, a cornerstone in the world of modern manufacturing and engineering, has a rich history that spans centuries. From its rudimentary beginnings to the sophisticated machines of today, the evolution of hydraulic presses is a testament to human ingenuity and the relentless pursuit of efficiency and precision in industrial processes.

The Genesis: The Concept of Hydraulic Power

The story of hydraulic presses begins with the fundamental principles of hydraulic power. The concept, which dates back to the works of Blaise Pascal in the 17th century, posits that pressure applied to a fluid is distributed evenly throughout the fluid. This principle laid the groundwork for the development of machines capable of exerting immense force through hydraulic means.

The 18th and 19th Centuries: Early Developments

The first hydraulic press was patented by Joseph Bramah in 1795. Known as the 'Bramah Press', this machine showcased the practical application of Pascal's law. It was initially used for tasks such as compressing agricultural products and forging metal. The Bramah Press marked the beginning of the era of hydraulic machinery, which would see significant advancements over the next century.

The Industrial Revolution: Expansion and Refinement

During the Industrial Revolution, hydraulic presses became integral to manufacturing processes. The 19th century saw these machines being used for metal forming, particularly in the burgeoning automotive and aerospace industries. The demand for stronger and more reliable components drove innovations in hydraulic press design, leading to increased efficiency and capability.

The 20th Century: Technological Advancements

The 20th century witnessed unprecedented technological advancements, and hydraulic presses were no exception. The introduction of electrically powered hydraulics, automatic control systems, and computer-aided design (CAD) revolutionized the operation and precision of these machines. Hydraulic presses became more versatile, capable of performing a range of tasks from stamping to molding with unprecedented accuracy.

The Modern Era: Sophistication and Specialization

Today, hydraulic presses are marvels of engineering, embodying sophistication and specialization. With advancements in materials science and digital controls, modern presses are highly efficient, environmentally friendly, and adaptable to a wide range of industries. From automotive to aerospace, and from metalworking to plastics, hydraulic presses continue to be indispensable tools.

Conclusion: The Future of Hydraulic Presses

The journey of the hydraulic press from a simple mechanical tool to a complex, highly efficient machine is a vivid example of technological evolution. As we advance into the future, hydraulic presses are poised to become even more sophisticated, with potential developments in automation, artificial intelligence, and materials technology. The legacy of the hydraulic press is not just its past achievements, but its ongoing contribution to innovation and industrial progress.