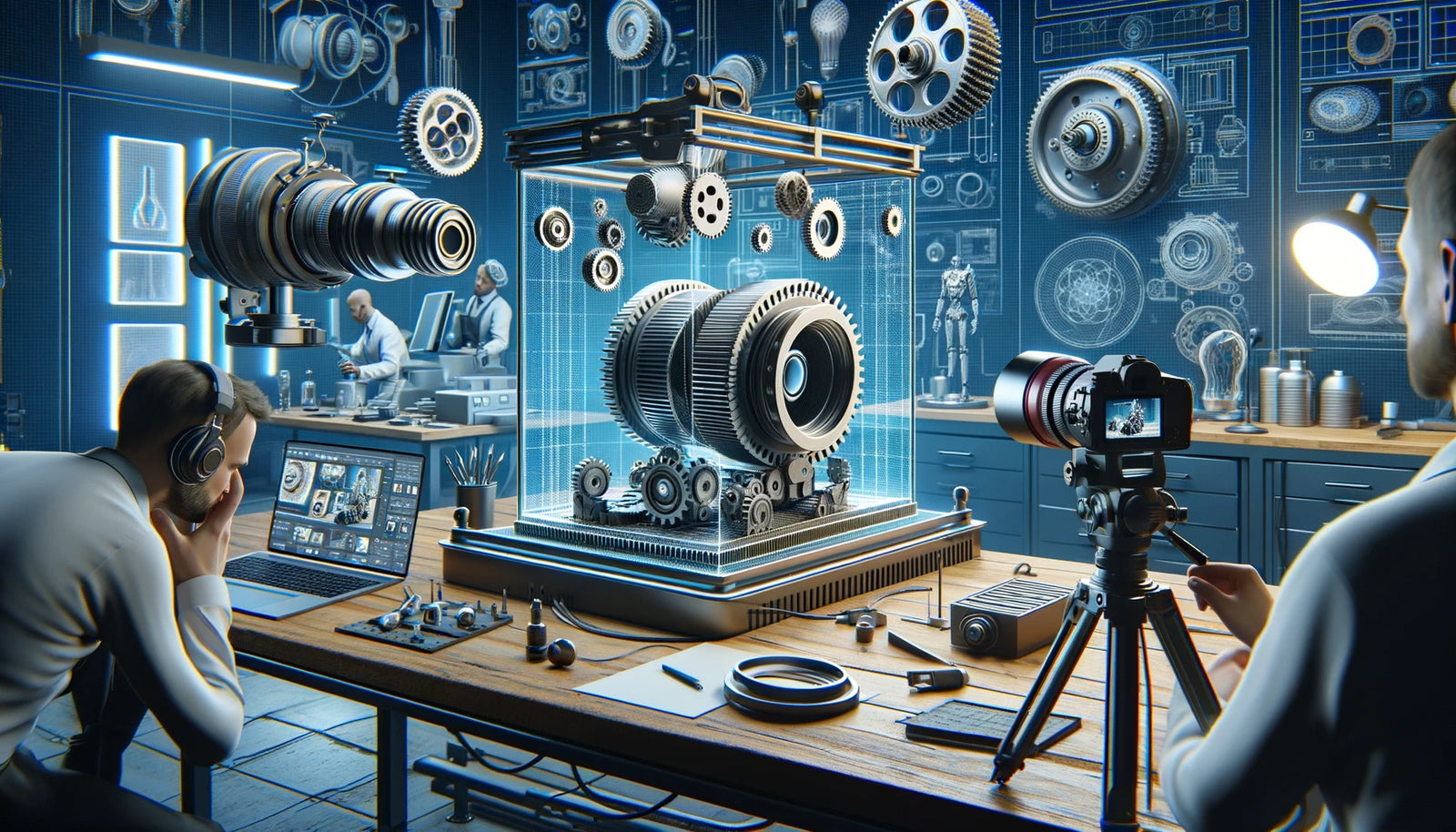

Reverse engineering is a critical process in the world of manufacturing, design, and quality control, enabling professionals to dissect, understand, and recreate components with or without the original blueprints at hand. In this intricate process, the choice of technology for capturing the physical attributes of an object to create a precise digital model is paramount. Photogrammetry, a method that uses photographs from different angles to reconstruct a 3D object, has emerged as a leading solution in the realm of reverse engineering. Here's why photogrammetry stands out as the best option for professionals looking to efficiently and accurately reverse engineer parts.

High Precision and Detail

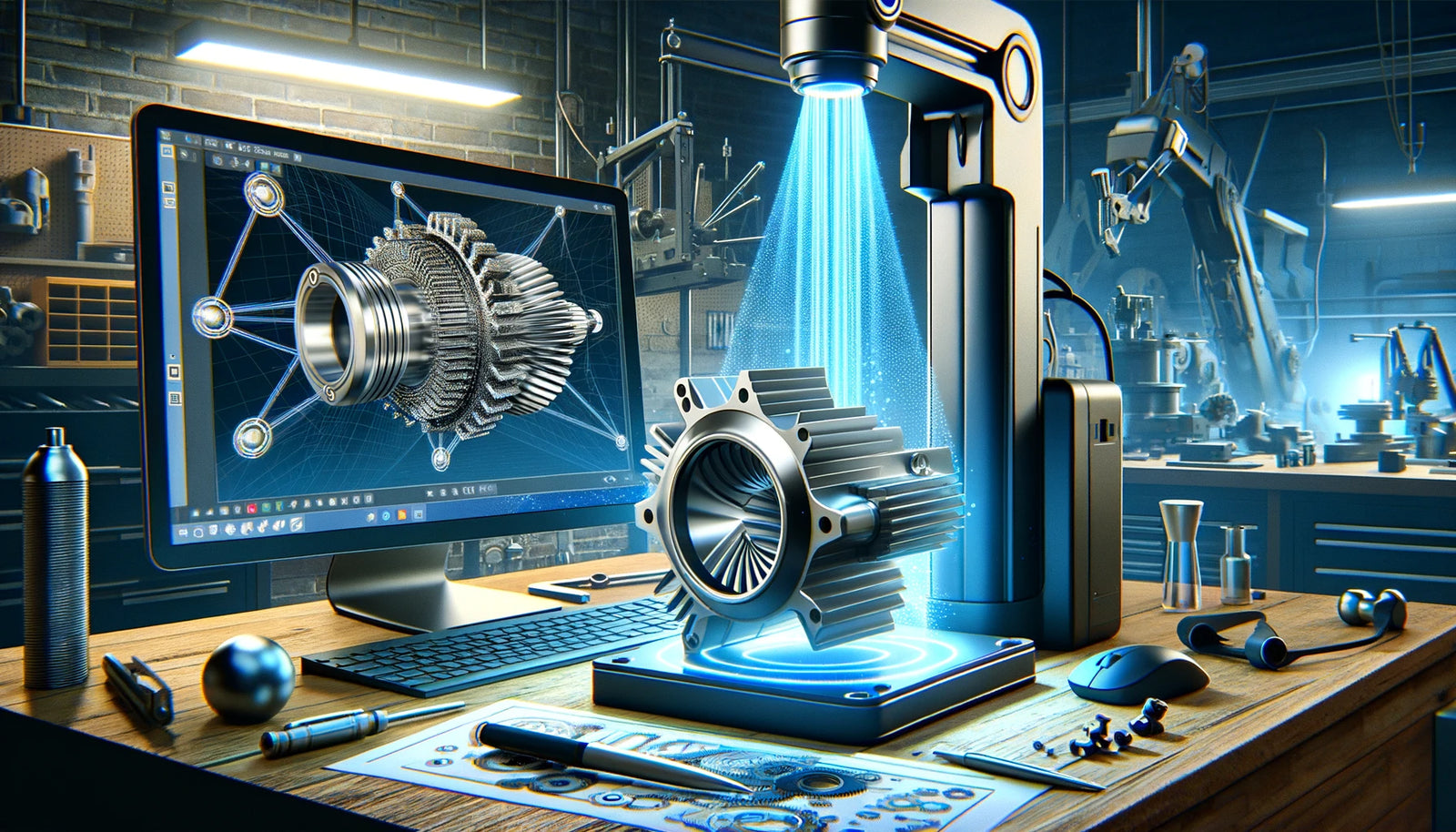

Photogrammetry excels in capturing the intricate details of an object through high-resolution photographs, making it incredibly effective for reverse engineering components with complex geometries. This precision is essential for creating accurate digital models that can be used to manufacture parts that fit seamlessly with existing systems or products.

Versatility and Accessibility

Unlike some 3D scanning technologies that require specialized equipment and can be limited by the size, material, or color of objects, photogrammetry is highly versatile. It can be performed with equipment as accessible as a high-quality camera or even a smartphone, making it an ideal option for a wide range of applications, from small components to large machinery.

Cost-Effectiveness

For businesses and individuals looking to adopt reverse engineering practices without significant upfront investment in expensive scanning equipment, photogrammetry provides an attractive solution. The lower barrier to entry in terms of cost allows companies to allocate resources towards other aspects of product development, such as CNC machining or 3D printing, to create the final component.

Ease of Use and Efficiency

Photogrammetry software has become increasingly user-friendly, with many solutions offering automated processes to guide users from photo capture to 3D model creation. This ease of use enables rapid capture and conversion of physical objects into digital models, significantly reducing the time between the scanning process and the availability of a model for editing or manufacturing.

Integration with CAD Software and Manufacturing Tools

The digital models generated from photogrammetry are compatible with a wide range of CAD software, allowing for easy editing, modification, and preparation for manufacturing. This compatibility is crucial for reverse engineering, as it enables the seamless transition from digital model to production with CNC machines or 3D printers, ensuring that the recreated part meets the required specifications and integrates perfectly with its intended system.

Scalability

Photogrammetry can easily scale from scanning small parts to large objects by simply adjusting the number and scale of photographs taken, without the need for different scanning equipment. This scalability makes photogrammetry a versatile tool in a company’s toolkit, capable of adapting to projects of different sizes and complexities.

Non-Invasive and Non-Destructive

Since photogrammetry is based on photography, it is a non-invasive and non-destructive method of capturing the geometry of objects. This characteristic is particularly valuable in reverse engineering sensitive or fragile parts, where contact-based measurement methods could cause damage or alter the object's state.

Conclusion

Photogrammetry offers a unique blend of accuracy, versatility, and cost-effectiveness, making it an invaluable tool in the reverse engineering process. By enabling quick and precise digitization of physical objects into editable and manufacturable 3D models, photogrammetry facilitates the seamless recreation of parts using CNC machining or 3D printing technologies. For businesses looking to streamline their reverse engineering processes, adopt efficient manufacturing practices, and innovate within their industries, photogrammetry represents a compelling solution that aligns with both technical needs and strategic objectives.

Dejar un comentario