Heavy-Duty Lathe Alignment and Calibration: What You Need to Know

Lathes are workhorses in the world of metalworking, known for their precision and durability. Whether you’re turning, facing, or threading, maintaining your lathe's alignment is critical for achieving consistent, high-quality results. Misalignment can lead to inaccurate cuts, tool wear, and even damage to the machine itself. In this guide, we'll walk through the essential aspects of aligning and calibrating your heavy-duty lathe to ensure peak performance.

Why Alignment Matters

Lathes rely on precision. Even small deviations in alignment can lead to inaccurate workpieces, poor surface finishes, and increased tool wear. Misalignment can also cause excessive vibration, which further degrades precision and can shorten the lifespan of your lathe.

In heavy-duty applications, where lathes are expected to work with larger workpieces and endure high stresses, proper alignment becomes even more critical. Without routine calibration, you risk compromising safety and efficiency.

Signs Your Lathe May Be Out of Alignment

Before diving into the calibration process, it's essential to recognize the signs of a misaligned lathe. Common indicators include:

- Uneven cuts: If you're noticing variations in the diameter of your workpiece along its length, it could be due to tailstock misalignment.

- Tapering: This occurs when the lathe bed or tailstock is misaligned, causing the part to taper from one end to the other.

- Poor surface finish: Increased vibration or misaligned components can cause irregular or rough finishes.

- Excessive tool wear: Tools that wear unevenly or rapidly are often a symptom of misalignment.

- Workpiece chatter: Misalignment often leads to excess vibration, producing a chattering sound and visible patterns on the workpiece.

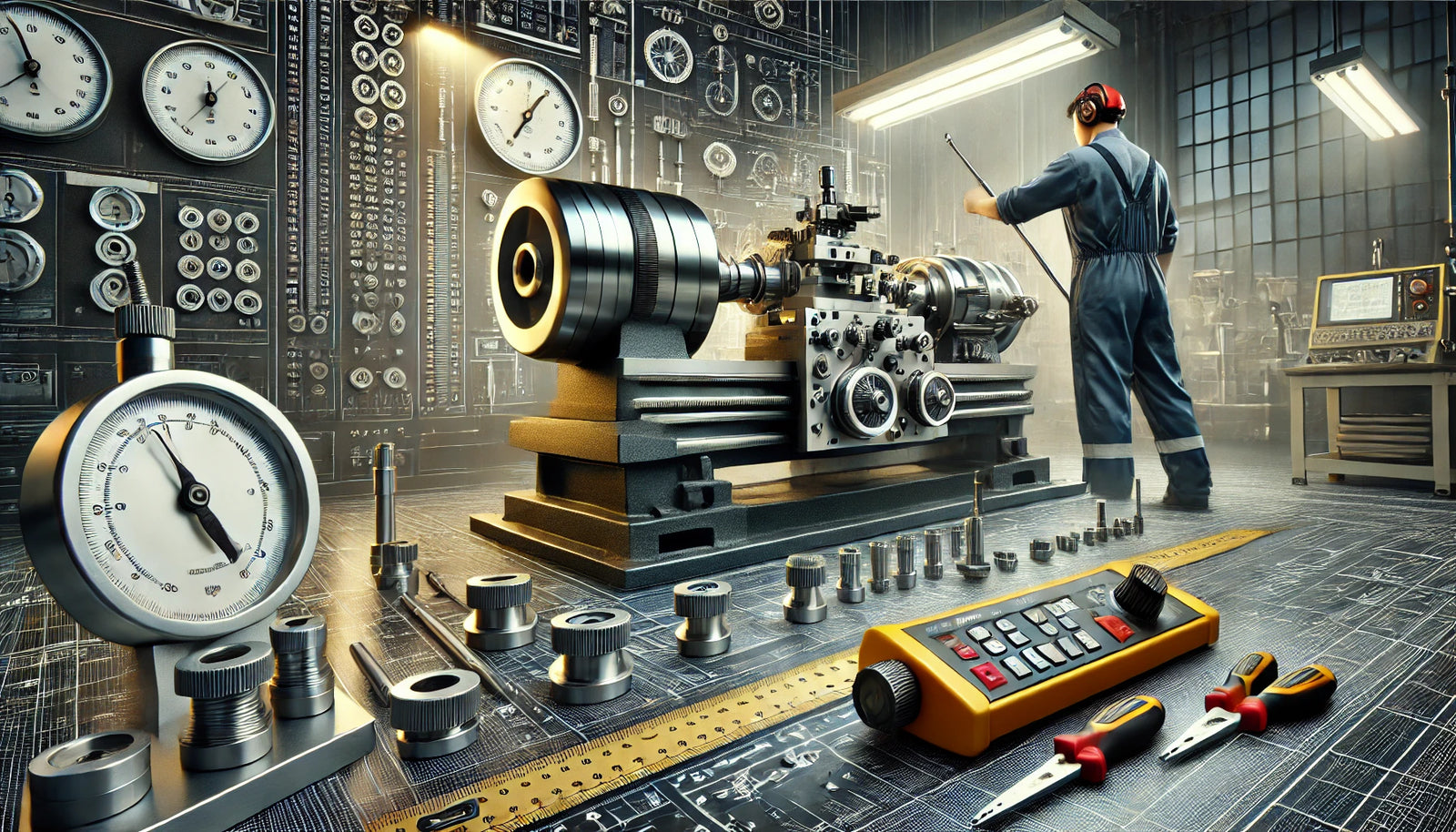

Tools You'll Need for Lathe Alignment

To properly align your heavy-duty lathe, you'll need a few essential tools:

- Dial Indicator: For measuring the runout and ensuring spindle accuracy.

- Straightedge or Precision Level: To check the levelness of the lathe bed.

- Micrometer or Calipers: To measure workpiece diameters and detect tapering issues.

- Lathe Test Bar: A precision bar used to check for alignment issues between the spindle and tailstock.

Step-by-Step Guide to Lathe Alignment

1. Check the Lathe Bed Leveling

The first step in aligning your lathe is ensuring the lathe bed is level. Even minor discrepancies in bed leveling can affect the precision of your work.

- Place a precision level or straightedge along the length of the lathe bed.

- Adjust the lathe’s leveling feet as needed, ensuring the bed is perfectly level from front to back and end to end.

2. Spindle Alignment

Ensuring the spindle is correctly aligned is crucial for avoiding workpiece inaccuracies and excessive wear.

- Mount a test bar in the spindle.

- Using a dial indicator, check for runout as you rotate the spindle slowly. The runout should be minimal (within 0.001 inches or less for most applications).

- If misalignment is detected, consult your lathe’s manual for the appropriate adjustments to bring the spindle back into alignment.

3. Tailstock Alignment

The tailstock is often a culprit when it comes to tapering issues. Misalignment here can lead to inaccurate cuts and uneven workpieces.

- With the test bar still mounted in the spindle, position the tailstock so that its quill is directly in line with the test bar.

- Use a dial indicator to check the alignment between the spindle and tailstock quill. The indicator should show no more than 0.001 inches of deviation along the length of the test bar.

- If needed, adjust the tailstock by loosening the locking bolts and making small corrections.

4. Cross-Slide and Carriage Alignment

For precise turning, the cross-slide and carriage need to be in perfect alignment with the lathe bed.

- Check for any excessive play or binding in the cross-slide movement. Adjust the gib screws as needed to ensure smooth operation.

- Ensure the cross-slide moves in a straight line by checking its travel with a dial indicator mounted to the carriage.

5. Test with a Workpiece

Once you've made the necessary adjustments, it's time to test your lathe alignment on an actual workpiece.

- Mount a piece of stock in the chuck and tailstock.

- Take a light test cut along the length of the part.

- Measure the diameter at both ends of the workpiece to ensure there is no taper. If the diameter varies, further adjustments to the tailstock alignment may be required.

Routine Maintenance for Keeping Alignment

Even after you've perfectly aligned your lathe, regular maintenance is crucial for maintaining its accuracy. Here's how to keep your lathe in top shape:

- Regularly inspect for wear: Components like the lathe bed, ways, and lead screws can wear over time, leading to misalignment. Perform routine checks and lubricate as necessary.

- Clean the machine frequently: Chips, debris, and coolant residue can build up and affect alignment. Make sure to keep the bed, ways, and other critical areas clean.

- Check alignment regularly: Periodic checks with your dial indicator, straightedge, and other alignment tools can prevent minor issues from turning into major problems.

Conclusion

Maintaining your heavy-duty lathe in perfect alignment and calibration is essential for producing high-quality workpieces and prolonging the life of your machine. By staying on top of alignment issues and performing routine checks, you'll ensure your lathe delivers consistent, reliable results over the long haul.

Proper alignment may seem tedious, but the time invested pays off in improved precision, reduced downtime, and lower maintenance costs. Keep your tools sharp, your machines aligned, and your production efficient.