Reverse engineering is a powerful tool in the modern design and manufacturing world, allowing engineers and designers to understand, replicate, or improve existing physical objects. This process involves deconstructing an object to discover its designs, architecture, or to extract knowledge from the object about its composition or manufacturing process. Traditionally, reverse engineering has been a time-consuming and often imprecise task, relying heavily on manual measurements and guesswork. However, the advent of 3D scanning technology has dramatically transformed the landscape, making the process faster, more accurate, and infinitely more versatile.

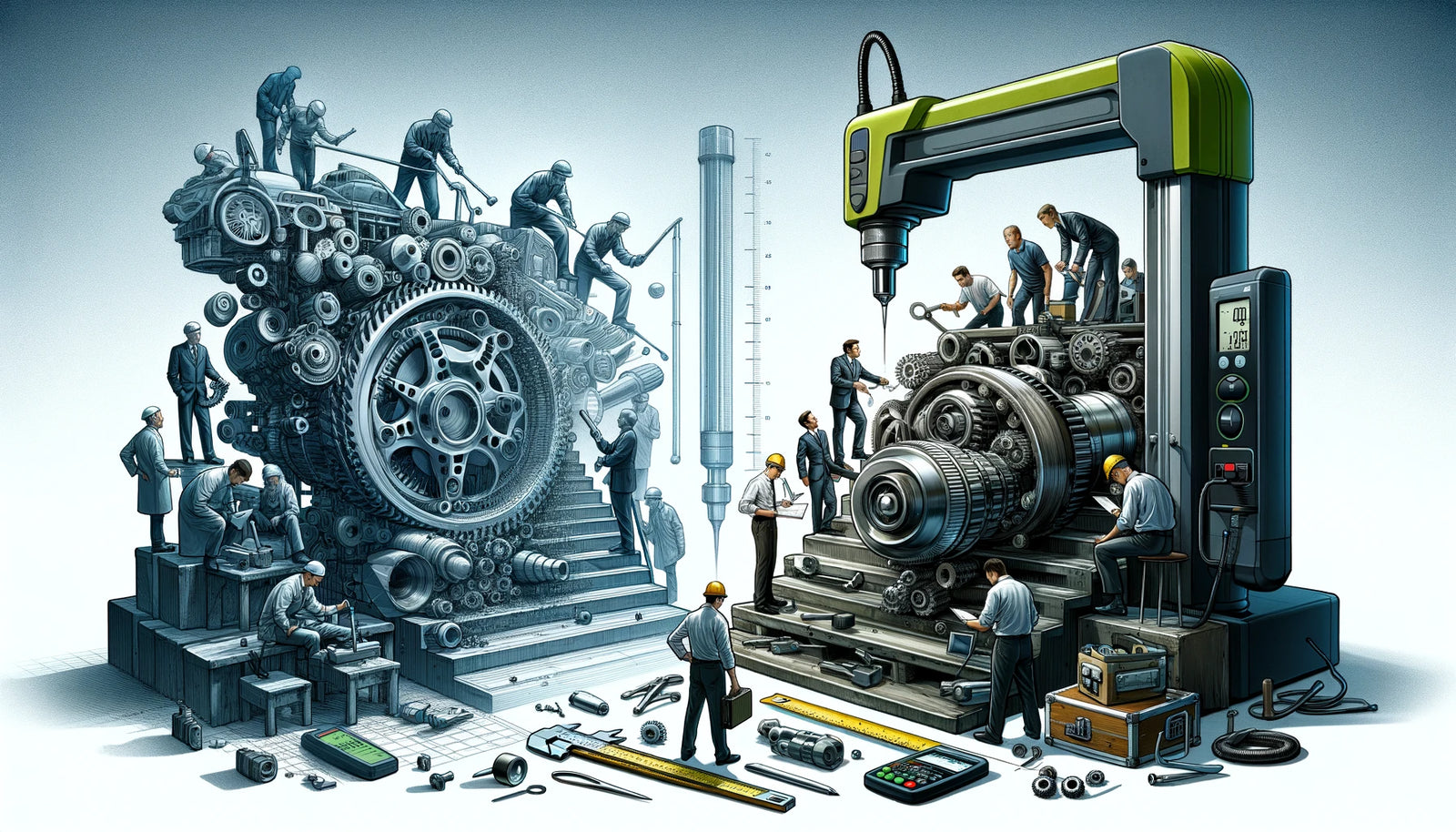

The Traditional Approach to Reverse Engineering

Traditionally, reverse engineering involved manually measuring every aspect of an object, a method that was not only slow but also prone to errors. Complex shapes could be particularly challenging to measure accurately, and the risk of human error was always present. The data collected then had to be painstakingly translated into a digital format, a process that required both time and expertise. This method was labor-intensive and required a high level of skill, making it inaccessible to many.

The Revolution Brought by 3D Scanners

The introduction of 3D scanning technology has revolutionized the process of reverse engineering by automating and significantly speeding up the data collection process. 3D scanners use laser, light, or x-ray to capture the shape of an object in three dimensions with high precision and detail. This digital representation can then be imported into CAD (Computer-Aided Design) software for analysis, modification, or reproduction. The benefits of this technology are manifold:

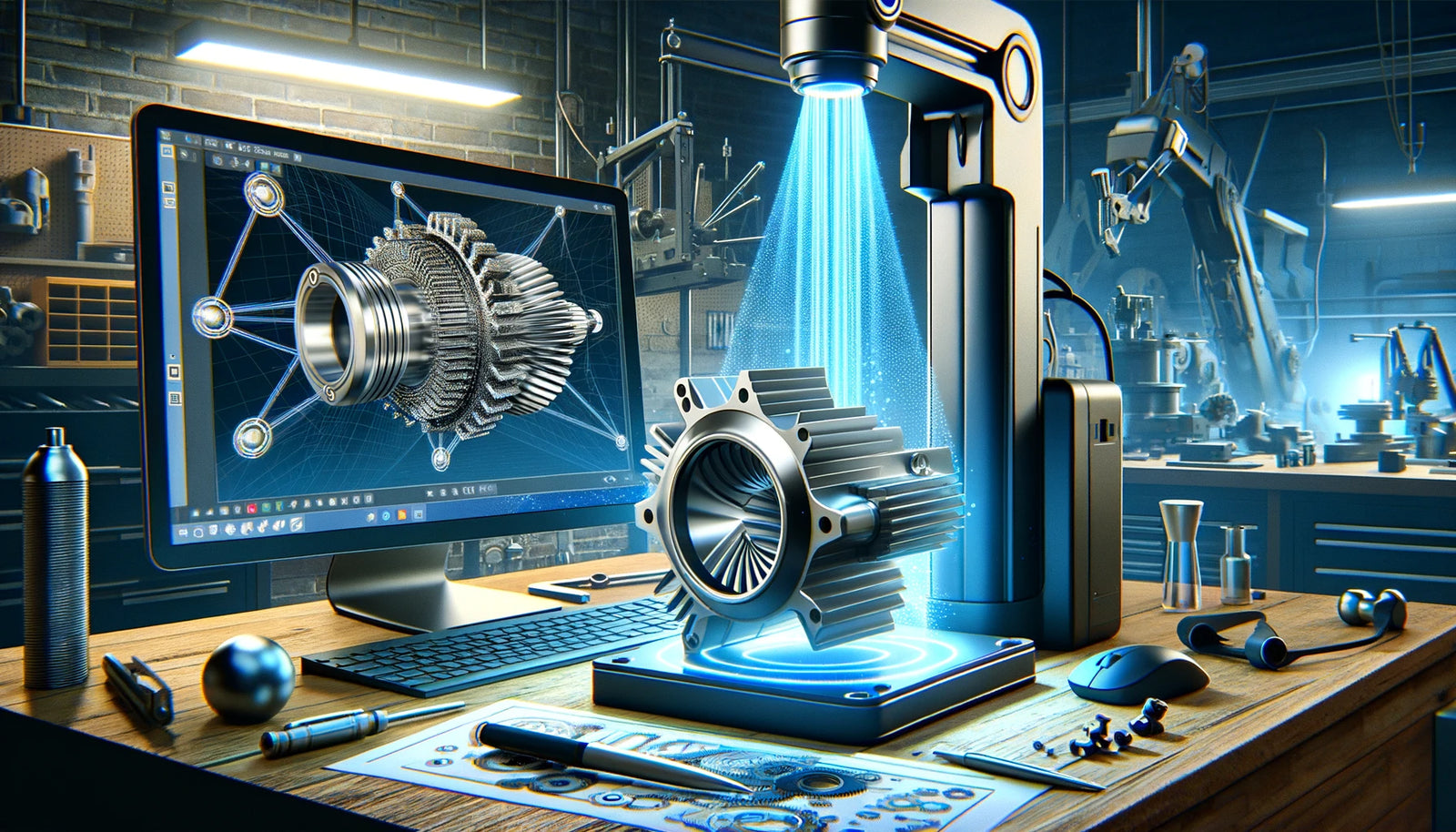

Precision and Accuracy

3D scanners can capture the minutiae of objects with incredible precision, making it possible to reverse engineer components with complex geometries or intricate details that would be difficult, if not impossible, to measure by hand. This level of detail ensures that the digital models created are accurate representations of the original objects.

Speed

What once took hours or days can now be accomplished in minutes. 3D scanning processes can capture millions of data points per second, allowing for the rapid digitization of objects. This efficiency not only speeds up the reverse engineering process but also enables the rapid prototyping and production of parts.

Versatility

3D scanning technology is versatile and can be applied to objects of virtually any size, shape, and material. This universality has opened up new possibilities in fields as diverse as aerospace, automotive, healthcare, and heritage preservation, where objects ranging from small components to entire buildings can be scanned and reverse-engineered.

Innovation and Improvement

By digitizing the reverse engineering process, 3D scanners have made it easier for engineers and designers to not just replicate objects, but to analyze them and propose improvements. CAD software can be used to tweak designs for better performance, cost efficiency, or sustainability, driving innovation in product development.

Democratization of Design

Finally, 3D scanning has democratized the reverse engineering process. High-quality scanners are becoming increasingly accessible, and simpler models can even be used by hobbyists and small businesses. This accessibility fosters creativity and innovation, allowing more people to participate in the design and manufacturing process.

Conclusion

The impact of 3D scanning technology on reverse engineering cannot be overstated. It has not only streamlined and improved the accuracy of the reverse engineering process but has also opened up new avenues for innovation, improvement, and democratization of design and manufacturing. As this technology continues to evolve, we can expect even greater advances in the ways we design, produce, and understand the world around us.

Leave a comment (all fields required)